In 1964, Franco Carloni begins to show interest towards ecology and the protection of water tables.

In 1967, starts filing patents for safety, ecology, energy saving and hydroelectric power applications.

In the ’70, designed a safety device that would later be used in F1.

In 1982, designed a liquids (hydrocarbons) crystallisation machine, thereby solving a huge diesel (37000 l) spillage affecting a drinking water source that flowed under a building of the municipality of Lugano and returning the water’s purity levels to 98%.

Formula 1

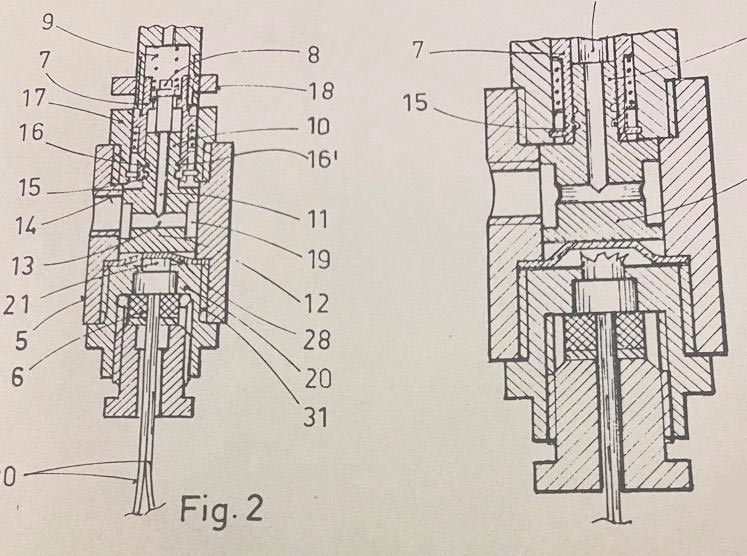

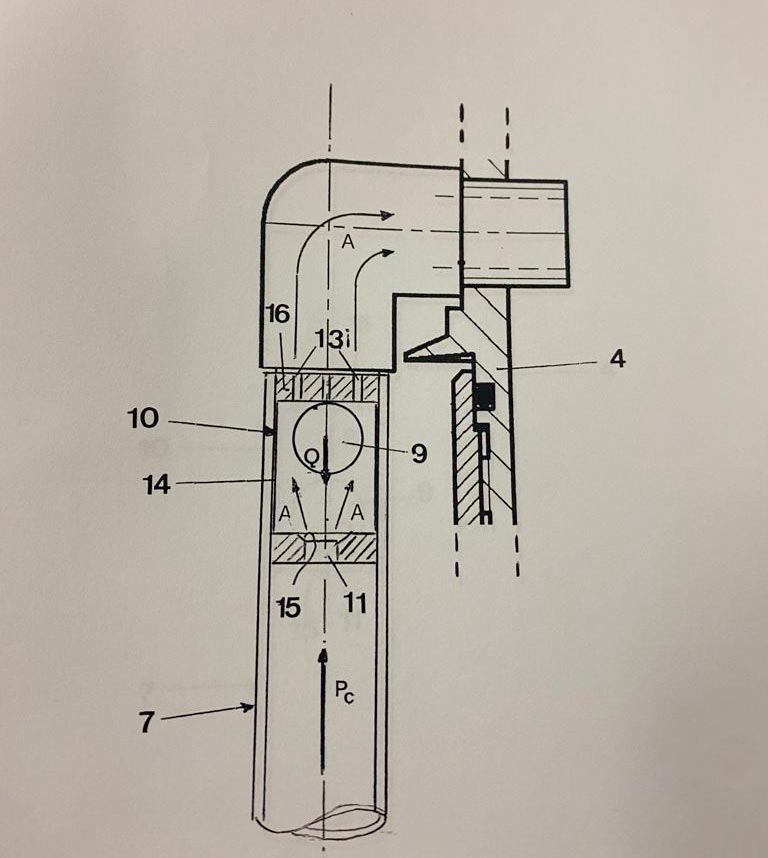

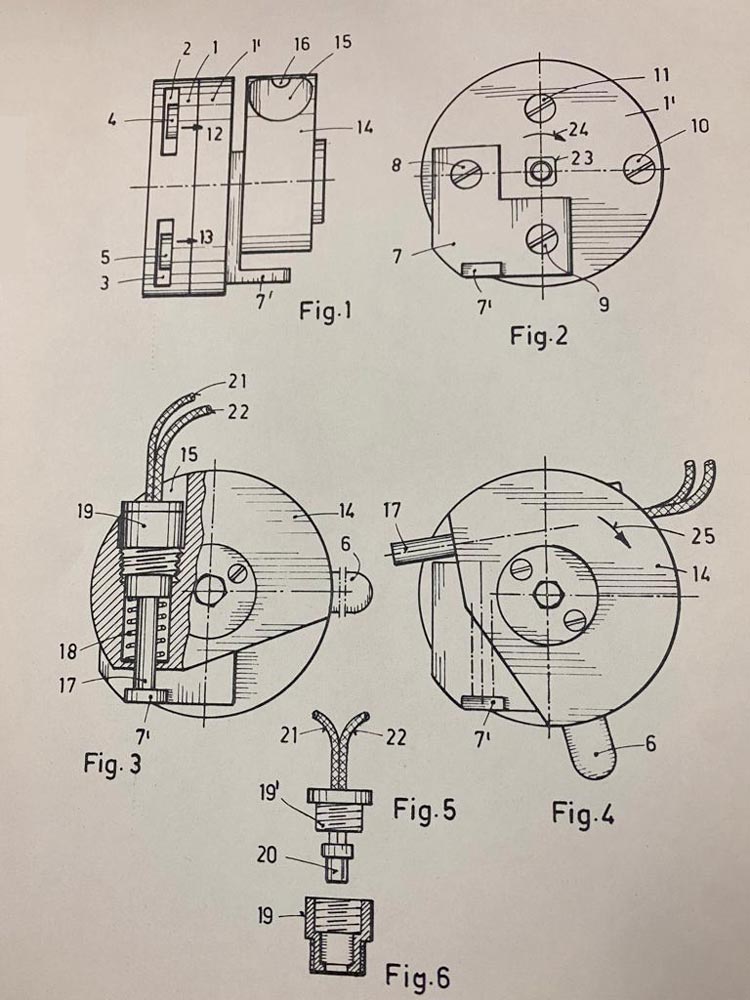

In 1976, Franco Carloni designed a specific helmet equipped with a breathing mask that helped protecting the pilot from smoke inhalation injuries during a fire.

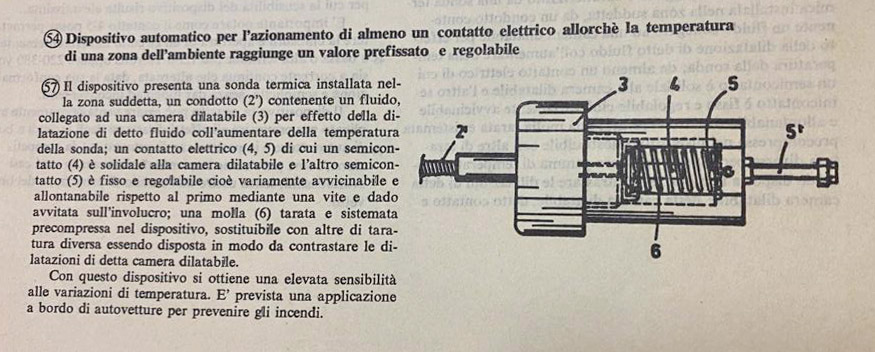

The helmet was connected to an automated installation (world first) which, when temperature exceeded 40 degrees in the cockpit and 90 degrees in the engine bay area, would automatically deploy fire extinguishers and alert the medical team, thus allowing the pilot to breathe for about three minutes.

His invention would be later used the Ferrari, Copersucar and Brabham Fromula 1 teams and by pilots such as Niki Lauda, Jilles Villeneuve, Jody Scheckter, Clay Regazzoni, Carlos Reutmann and Emerson Fittipaldi and continued to be used up until the late ‘80s, just before the start of the turbo era.

Energy Saving

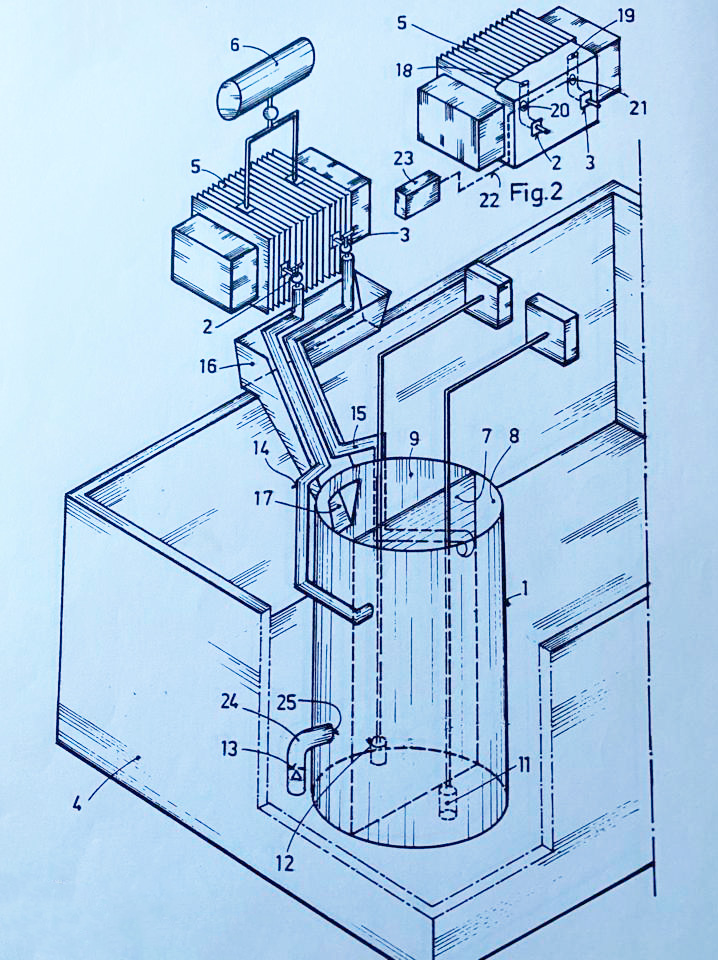

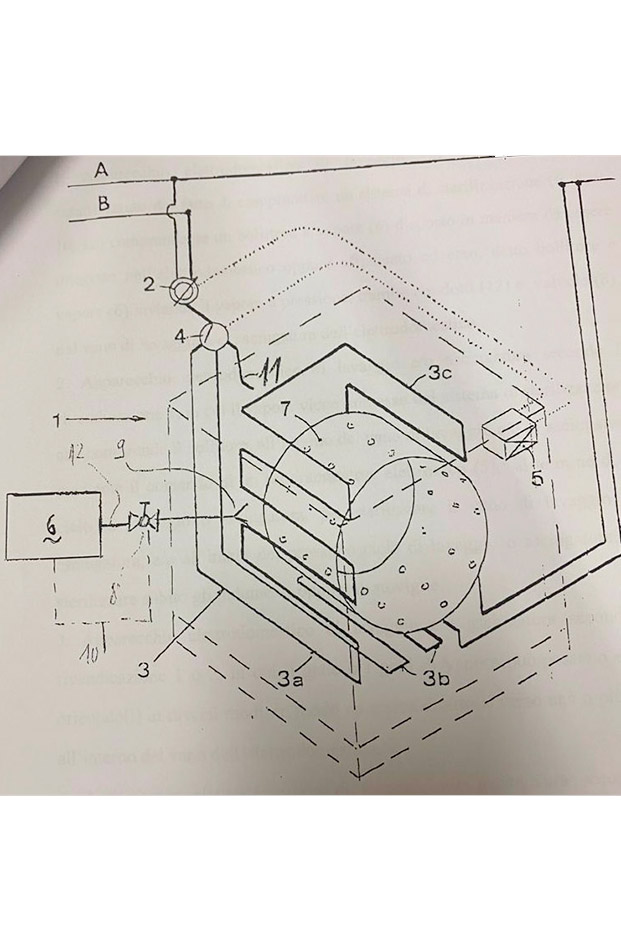

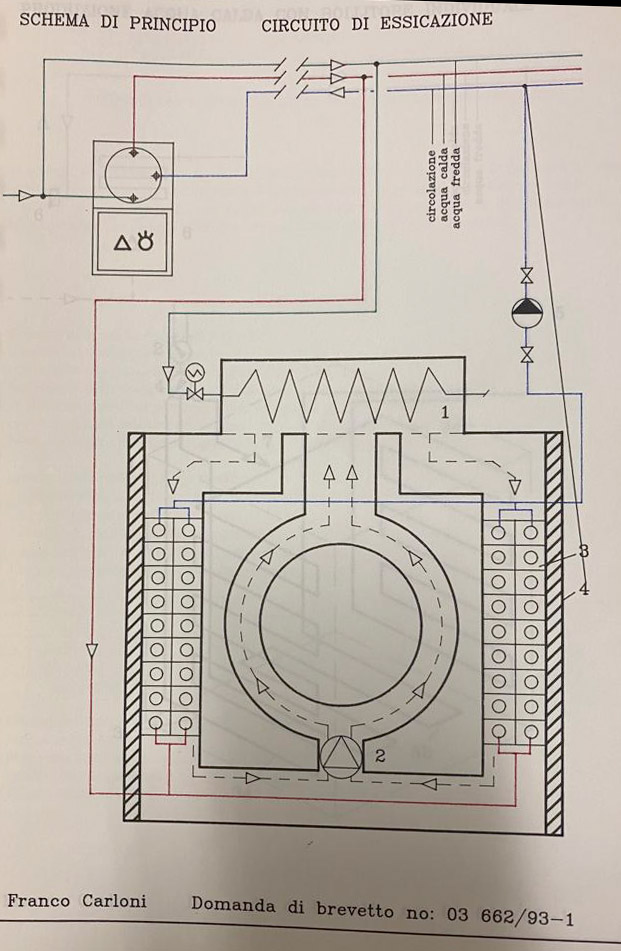

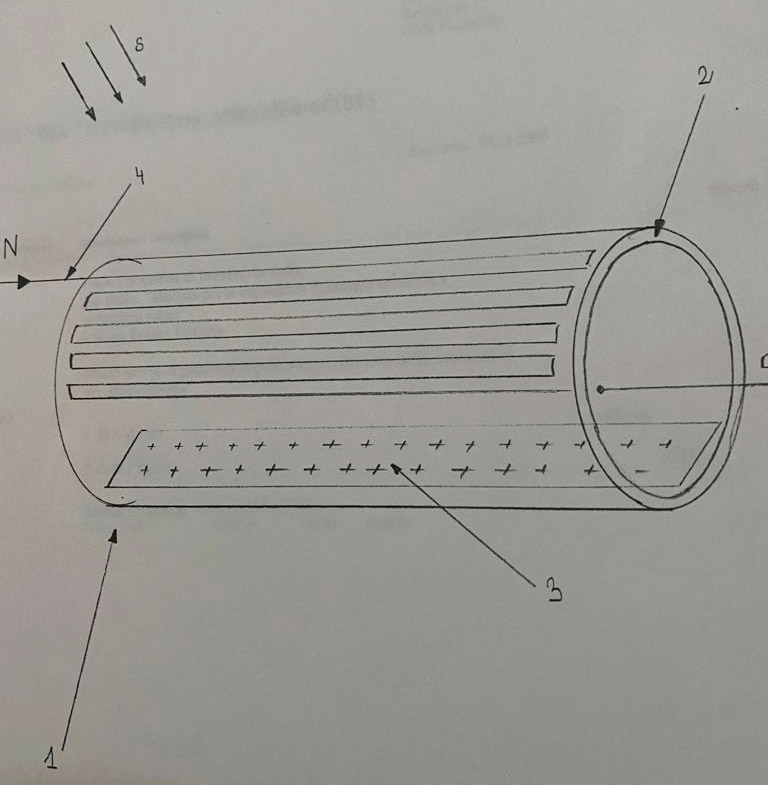

By 1989, Franco Carloni had already shown a strong interest in energy saving and acoustic comfort applications. He patented the project and constructed the building called Residence 51, in Camorino (CH).

The name of the building derives from the fact that following sound insulation tests, it emerged that noise pollution had been reduced to 51 dB at 500 Hz, a level close to absolute silence (36 dB).

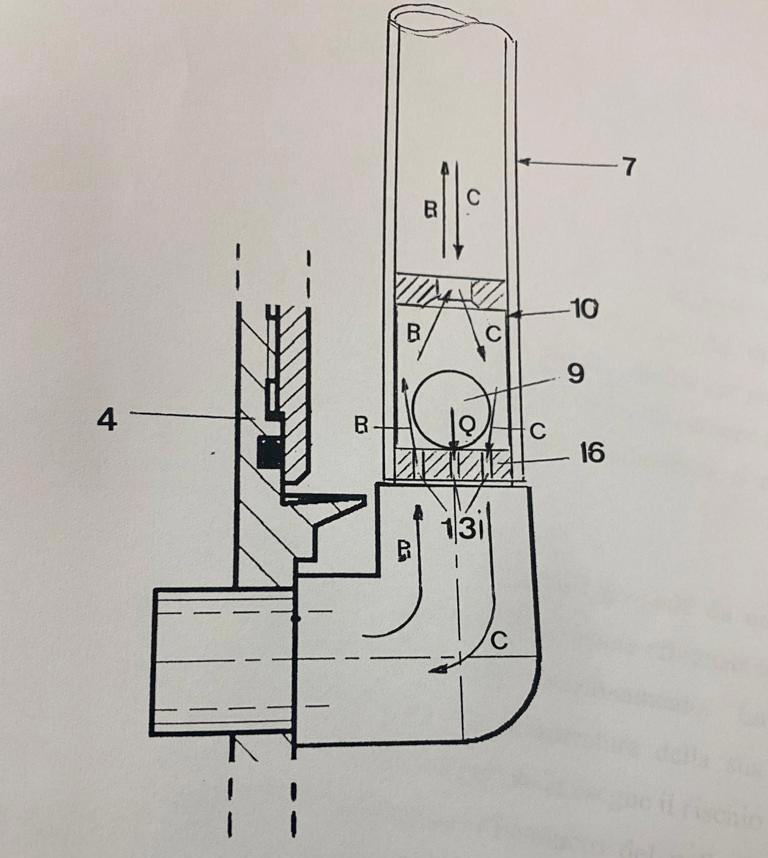

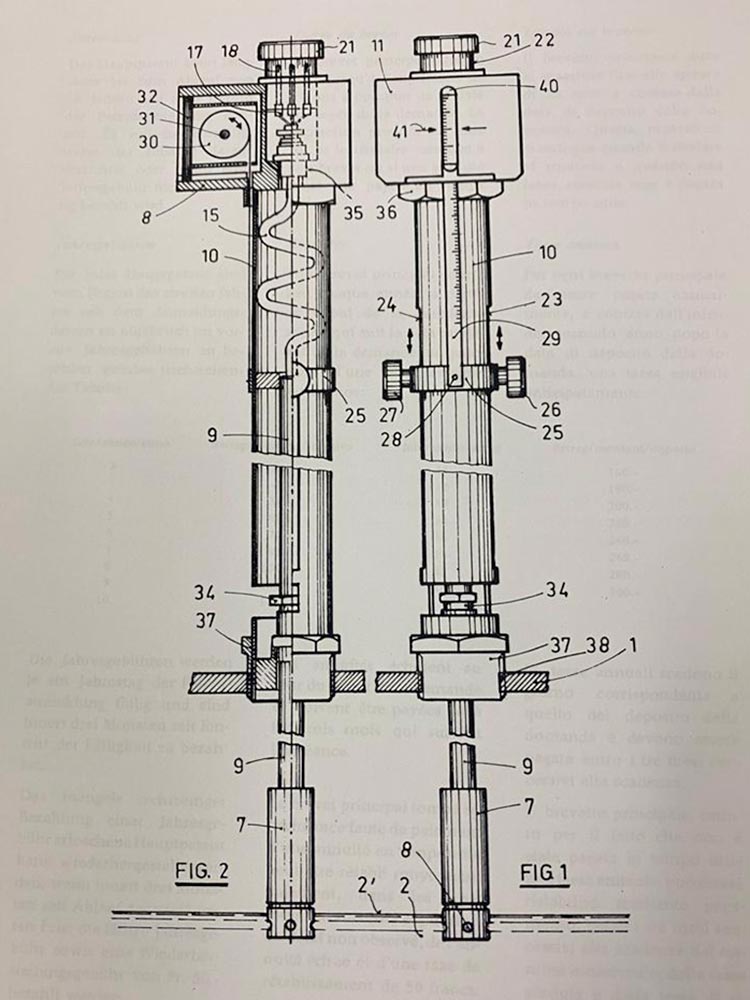

To obtain this performance, the perimeter walls consisted of two separate walls, air flowing naturally in between, hence the acoustic comfort and thermal insulation value of K 5.5.

The patent also provided for, water table permitting, a system that would use the constant temperature of the water table to cool or heat the air inside the building.

Illuminated Balloons

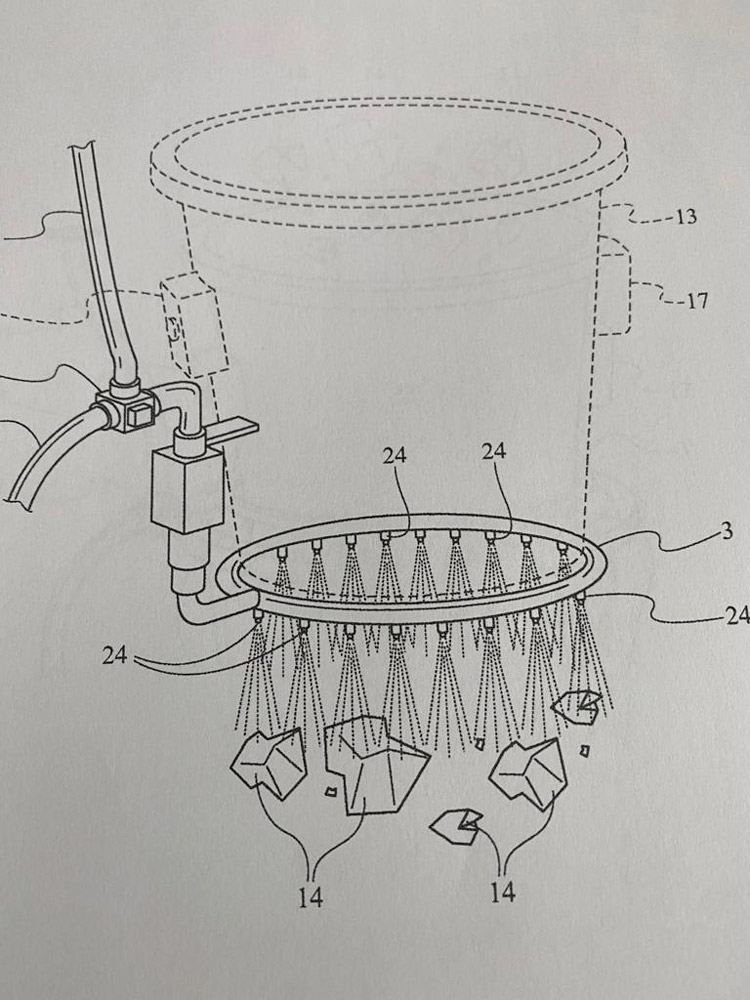

In 1995, Franco Carloni patented, as a world first, a luminous balloon (initially filled with helium and subsequently air) that was used to provide 360 degrees non-dazzling lighting.

The balloon is able to illuminate an area of 250 metres in absolute darkness, using an energy source of only 1200 watt.

This type of technology is still in use today in a multitude of applications ranging from public or private events to ensure lighting in darks areas affected by catastrophic events.